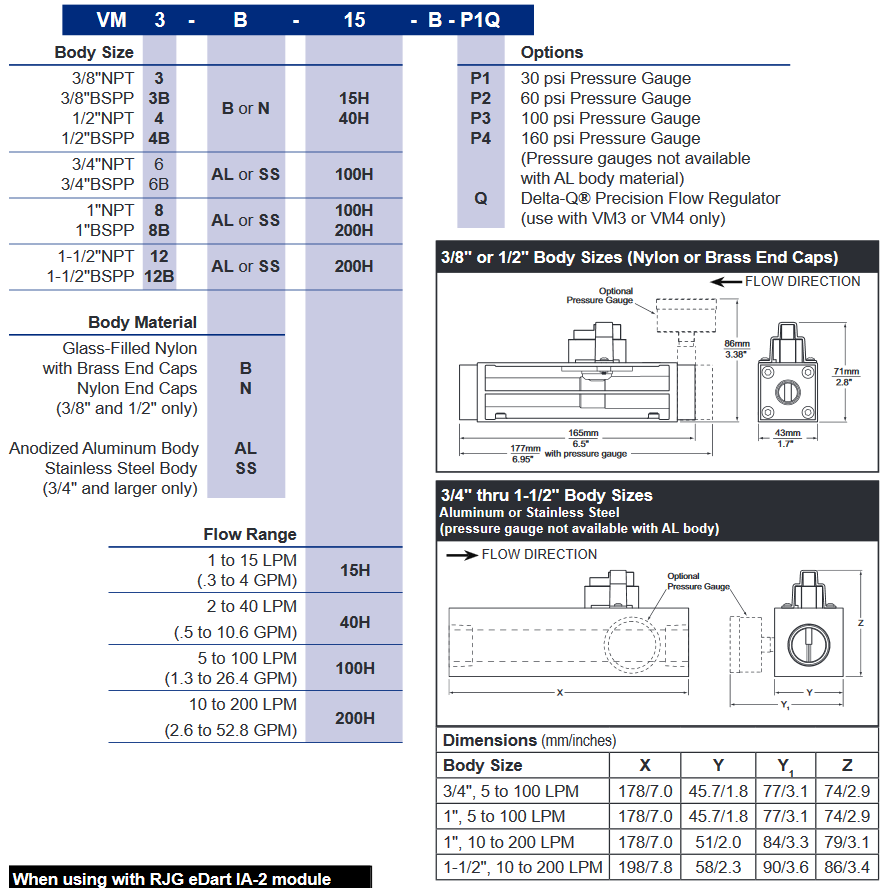

The Tracer VM Flowmeter is a non-display sensor that provides a 0.5 to 3.5 Volt output for process flow rate and a 0.5 to 4.1 Volt output for process temperature. Vortex sensor technology is highly accurate and repeatable without moving parts. Flow reading is direction specific. Refer to the arrow on the body for correct installation. Connection to the process is made using standard pipe threads in NPT or BSP from 3/8″ through 1-1/2″. Flow body materials are corrosion-resistant brass, nylon, anodized aluminum and stainless steel. Options are based on thread size, see page 2 for details.

The flow meter is designed for use in industrial water applications such as injection mold cooling or filter and pump monitoring.

| 1 to 15 LPM | (.3 to 4 GPM) | 3/8″ or 1/2″ |

| 2 to 40 LPM | (.5 to 10.6 GPM) | 3/8″ or 1/2″ |

| 5 to 100 LPM | (1.3 to 26.4 GPM) | 3/4″ or 1″ |

| 10 to 200 LPM | (2.6 to 52.8 GPM | 1″ or 1-1/2″ |

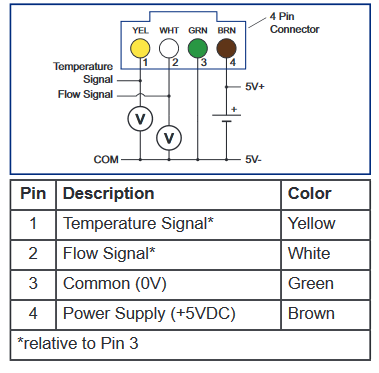

Power Supply – 5VDC +5% (external)

Output Signals – Ratiometric

Flow Signal – 0.5 – 3.5V (zero at 0.35V)

Temperature Signal – 0.5 – 3.5V

Power consumption – < 50mW Load Impedance > 10 kQ

Sensing Element – Silicone Based MEMS Sensor

Seal (sensor to housing) EPDM Rubber

Insert – PPA 40 GF

3’8″ & 1’2″ body size – Glass Filled nylon flow body with brass or nylon end caps

3/4″ thru 1-1/2″ body size – anodized aluminum or stainless steel flow body