System cooling offers injection molders an exclusive and affordable solution for monitoring flow and temperature circuits within an injection mold.

The efficiency of the mold cooling circuits are critical to a stable process and the manufacturer of high quality, dimensionally stable parts. System Cooling can protect your mold and improve quality by quickly identifying coolings problems and alerting the user to various common cooling circuit problems such as:

Molders that run parts with critical tolerances and require consistency of mold cooling can generate reports to support their industry certifications.

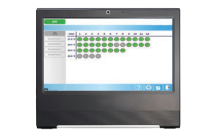

Touch Screen Controller

Using a remote, mounted touch screen the system will minotr and display the flow and temperature for every circuit. The touch screen is used to:

The user can see an immediate overview of cooling circuit status ‘at a glance’ on a singles screen with instant display status alarms should the flow / temperature go outside of tolerance.

Historical data recording means that a performance log for each circuit and manifold is stored on the internal memory, allowing the user to track the performance and easily identify problems.

Alarm errors, warnings and operator changes are all stored with a time and date stamp and can be reviewed at any time.

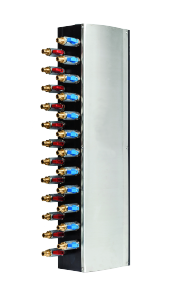

The slim line and compact design has been developed to enable the System Cooling manifold to be mounted into the smallest space possible next to the machine platens, keeping pipe runs to an absolute minimum, improving flow rates to the mold and reducing cycle times. Other notable features include:

The System Cooling Manifold is equipped with very compact sensors that are capable of reading both flow and temperature:

System Cooling is equipped with a DIN-Rail mounted interface module (MFIO) – this is the hub of the system and allows the manifolds to be easily connected to external devices.

AST can offer custom solutions where the electronics is built into the machine control panel and integrated directly into the injection molding machine.

The manifold is equipped with network-ready electronics and can be connected to the network/internet via the ethernet connection.

New Molds

Moldmakers must often supply new molds to the xustomer complete with a report of operating parameters including data relating to the cooling circuits in the mold. Now moldmakers can easily connect the System Cooling Test Rig to the mold as part of the benchmarking process.

Mold Maintenance

Mold cooling circuits need to be maintained regularly to remove scale and rust to ensure maximum productivity. With the System Cooling Test Rig, the cooling channels can be analyzed and tested. The flow and pressure can be precisely controlled to simulate the production setup.

After maintenance users an generate fully documented reports from any location, directly on a smartphone or laptop, certifying that all flow and pressure values are regained. The reports generated document: