| Model | Inlet | Outlet |

|---|---|---|

| WDT2-N2-N4 | 1/4 ” NPT(F) | 1/2″ NPT(F) |

| WDT2-SP-P2 | 1/4″ Quick Connect Socket | 1/2″ Quick Connect Plug |

| WDT2S3-P3 | 3/8″ Quick Connect Socket | 3/8″ Quick Connect Plug |

| WDT2-N2-N4-M | 1/4″ NPT(F) 7 port Manifold | 1/2″ NPT(F) |

| WDMF-100: MANIFOLD ONLY | 1/4″ NPT(F) 7 port |

Physical

Material – All wetted parts are Electroless Nickel-Plated Brass & Stainless Steel

O-Rings – Buna-N

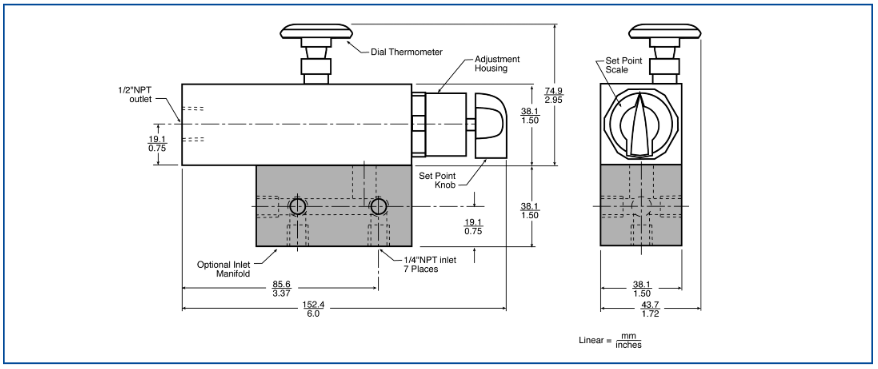

Inlet Size – 1/4″ NPT(F)

Outlet Size – 1/2″ NPT(F)

Maximum Pressure – 125 psi (8.6 bar)

Weight – 3 lbs (1.5 kg)

Dial Thermometer:

Range – 0 to 250°F (-18 to 121°C)

Accuracy – +1°F Mid Scale, +2°F Full Scale

Traditionally, high turbulent flow rates are used in cooling water loops to achieve acceptable heat transfer rates from the mold. High turbulent flow rates are irrelevant when using the Smartflow Mold Temperature Regulator. It regulates cooling water flow leaving the mold to achieve Set Point temperature. The unit is unaffected by supply cooling water pressure and temperature. For example, it automatically compensates for temperature changes of cooling tower water between night and day.