Description

3/4″ Aluminum Manifolds (6SA Prefix)

Smartflow Aluminum Manifolds are constructed from unique extruded material, precision machined, then anodized for corrosion protection. Many manifold sizes are stocked, and custom manifolds can be made to your specifications.

Standard red and blue colors denote supply and return for cooling water lines. 3/4″, 1″ and 1/1/2″ manifolds are equipped with dovetail locking channels, pre-drilled mounting holes, and bolts for ease in pairing and installation. Each manifold with NPT threads includes one bronze end plug.

Features and Benefits

- One-Piece Extruded Aluminum Construction is lightweight with long-lasting durability.

- Quality Anodizing protects the manifolds from corrosion and signifies manifold function.

- Different Port Size Options provide connection flexibility.

- Bronze End Plug is included for customer convenience (NPT threaded manifolds only).

- Pre-Drilled Mounting Holes make the manifolds ready to install.

- 3/4 thru 1-1/2 manifolds dovetail together for ease and mounting

- Common Manifold Configurations are stocked for quick delivery

Specifications

- Material – Aluminum (6000 Series)

- Max Pressure – 150 psi (10 bar)

- Max Temperature – 300 degree F (149 degrees C)

- Anodizing – Mil Spec Type II Class 2

- Standard Colors – Red, Blue

Assembly

Smartflow aluminum manifolds are the platform for control of cooling water lines in most types of industrial process cooling. Injection molding is one example of our particular area of expertise. Flowmeters, Flow Regulators, Ball Valves, Quick Disconnect Fittings and more can be added to the manifolds to improve functionality and process control.

Custom Manifolds

Special port sizes and location are possible with Smartflow aluminum manifolds. All fabrication is done from extruded material.

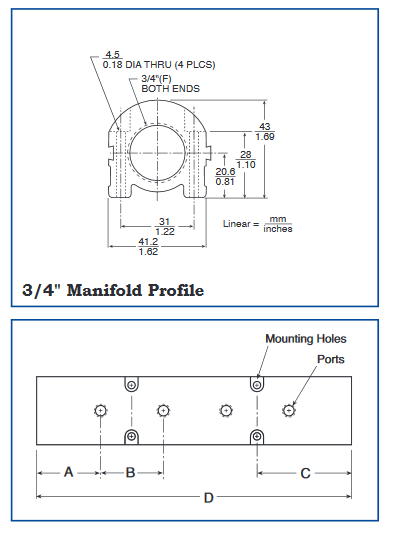

| Stocked 3/4″ Manifolds | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Number of Ports | 1/4″ Ports A = 38.1mm/1.5″, B = 38.1mm/1.5″ C = 57.2mm/2.25″ |

3/8″ Ports A = 38.1mm/1.5″, b=50.8mm/2.0″, C= 63.5mm/2.5″ |

|||||||||

| Model Number | mm | in. | kg | lbs. | Model Number | mm | in. | kg | lbs. | ||

| 4 | 6SA-4-2-2 | 190 | 7.5 | 0.5 | 1.1 | 6SA-4-3-2 | 229 | 9 | 0.6 | 1.4 | |

| 6 | 6SA-6-2-2 | 267 | 10.5 | 0.7 | 1.6 | 6SA-6-3-2 | 330 | 13 | 0.9 | 2.0 | |

| 8 | 6SA-8-2-2 | 343 | 13.5 | 0.9 | 2.0 | 6SA-8-3-2 | 432 | 17 | 1.2 | 2.6 | |

For help with your manifold configuration, please visit our online manifold building tool — visit manifoldbuilder.com

3D CAD files for manifolds and assemblies are also available upon request. Please contact a sales rep: sales@acetronic.com for more details.