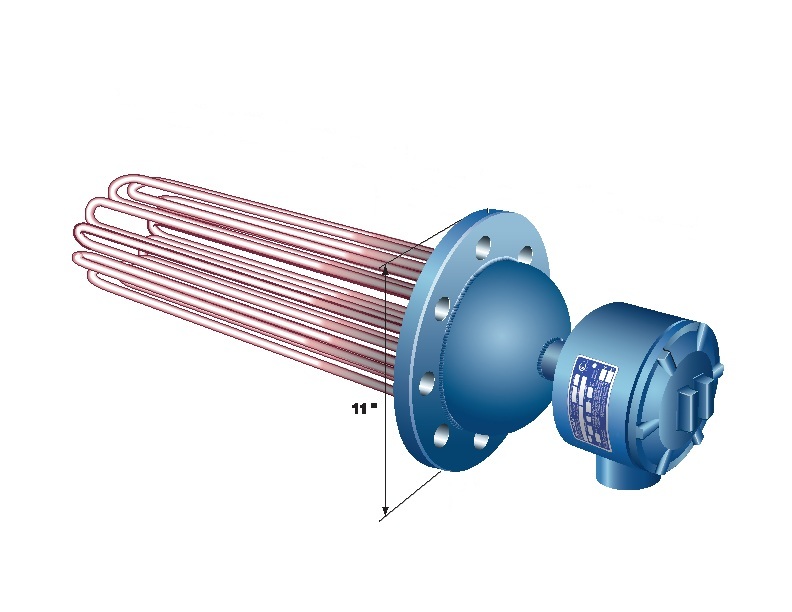

Flanged immersion heaters are high capacity electrical heating units made for tanks or pressurized vessels. They consist of multiple tubular heaters formed into hairpin and welded or brazed to flanges. The heating elements could be made of copper, steel, stainless steel or Incoloy sheath. Standard flanges are carbon steel rated for 150 or 300 Lbs. Other flange materials and shapes are available. Various types of electrical protection housing, built in thermostats, thermocouples and high limit switches can be incorporated.

| 150 Lbs. Flange detail rating | 300 Lbs Flange detail rating | |||||||||||

| Size | Max # of elements | Standard cold end | O.D. | Flange thickness | # Holes | Holes diameter | B.C. | O.D. | Flange thickness | # Holes | Holes diameter | B.C. |

| 2.5″ | 3 | 5 1/2″ | 7″ | 7/8″ | 4 | 3/4″ | 5 1/2″ | 7 1/2″ | 1″ | 8 | 7/8″ | 5 7/8 |

| 3″ | 6 | 5 1/2″ | 7 1/2″ | 15/16″ | 4 | 3/4″ | 6″ | 8 1/4″ | 1 1/8″ | 8 | 7/8″ | 6 5/8″ |

| 4″ | 9 | 5 1/2″ | 9″ | 15/16″ | 8 | 3/4″ | 7 1/2″ | 10″ | 1 1/4″ | 8 | 7/8″ | 7 7/8″ |

| 5″ | 9 | 6 3/4″ | 10″ | 15/16″ | 8 | 7/8″ | 8 1/2″ | 11″ | 1 3/8″ | 8 | 7/8″ | 9 1/4″ |

| 6″ | 18 | 6 3/4″ | 11″ | 1″ | 8 | 7/8″ | 9 1/2″ | 12 1/2″ | 1 7/16″ | 12 | 7/8″ | 10 5/8′ |

| 8″ | 30 | 6 3/4″ | 13 1/2″ | 1 1/8″ | 8 | 7/8″ | 11 3/4″ | 15″ | 1 5/8″ | 12 | 1″ | 13″ |

| 10″ | 48 | 10″ | 16″ | 1 3/16 | 12 | 1″ | 14 1/4″ | 17 1/2″ | 1 7/8″ | 16 | 1 1/8″ | 15 1/4″ |

| 12″ | 60 | 10″ | 19″ | 1 1/4″ | 12 | 1″ | 17″ | 20 1/2″ | 2″ | 16 | 1 1/4″ | 17 3/4″ |

| Bundle diameter to suit sch. 80 pipe | ||||||||||||

Flanged immersion heaters can be used in different applications. In order to meet the heating requirements of a specific application and have a safe operation in the environment within which a heater operates several factors should be taken into consideration in the design of flanged immersion heaters. The following are a number of criteria that should be considered:

| Sheath Material | Maximum Temperature |

| Copper | 3600 F (1800 C) |

| Stainless Steel | 12000 F (6500 C) |

| Steel | 7500 F (4000 C) |

| Incoloy | 15000 F (8150 C) |

For more information in selecting Flanged immersion heaters please Contact Sales.

| Application | Sheath Material | Flange | Typical Watt Density |

| Clean water | Copper | Steel | 45 |

| Process water/Weak solution | Stainless Steel | Stainless Steel | 25-55 |

| Oil light | Steel | Steel | 20-25 |

| Oil medium | Steel | Steel | 12-15 |

| Corrosive solutions | Incoloy | Stainless Steel | 20-25 |

| Vegetable oil | Stainless Steel | Stainless Steel | 25-30 |

| Asphalt, tar, wax | Steel | Steel | 6 |

| Air | Incoloy | Steel | 23 |

The thermostats used in flanged immersion heaters are the bulb and capillary style. The standard thermostat has 25A max capacity and could operate up to 240V. This thermostat is single pole/single throw style with a temperature range of 10-120ºC. The table below shows other ranges of thermostats that are available.

| THERMOSTAT | CONTACT OPERATION | TEMPERATURE RANGE | MAXIMUM AMPS | MAXIMUM VOLTAGE |

| T | SPST | 100 to 1200 C | 25A | 277V |

| T1 | SPST | -180 to 400 C | 25A | 277V |

| T2 | SPST | 700 to 2800 C | 25A | 277V |

| T3 | SPST | 1600 to 3700 C | 25A | 277V |

| T4 | DPST | 100 to 1200 C | 15A | 600V |

| T5 | DPST | -180 to 400 C | 15A | 600V |

| T6 | DPST | 700 to 2800 C | 15A | 600V |

| T7 | DPST | 1600 to 3700 C | 15A | 600V |

It should be noted that thermostats are only temperature controllers and should not be used as fail-safe high limit switches.

Built-in thermocouples could be used inside flanged immersion heaters to give more accurate temperature indications. Thermocouples could also be attached to one of the heating elements and used as high-temperature limiting devices.

|

|

|

|

|

|