Description

General Description

Smartflow High Pressure and Temperature manifolds and Assemblies are designed for use in hot oil or water cooling systems up to 400 degrees Fahrenheit (204 degrees Celsius).

Smartflow manifolds are ideal for connection to temperature control units in an injection molding environment. The manifolds are available with 1″ and 1-1/2″ inlet sizes (one end only) and 1/2″ ports. Optional Flowmeters and regulators are constructed of stainless steel with high temperatures seals for corrosion free options and long trouble-free service life.

Specifications

Manifold

Material: Stainless Steel

- Pressurized hot water cooling systems up to 450 degrees F (232 degrees C), 450 psi (31 bar)

- Hot oil cooling systems up to 600 degrees F (315) degrees C), 100 psi (6.9 bar)

Optional Flowmeters

Viewing Window: Glass

Vane: Stainless Steel

Spring: Stainless Steel

Pin: Stainless Steel

Gasket: Non-Asbestos Fiber

Magnet: Sintered Alnico 8GE

Accuracy: +10%

Flow Rate: 6 GPM or 22 LPM

Optional Flow Regulators

Material: Stainless Steel

O-Rings: Viton

Caution: Potential for personal injury exists in application of this product. Appropriate thread sealant, hoses and fittings must be used with high pressure and temperature manifolds.

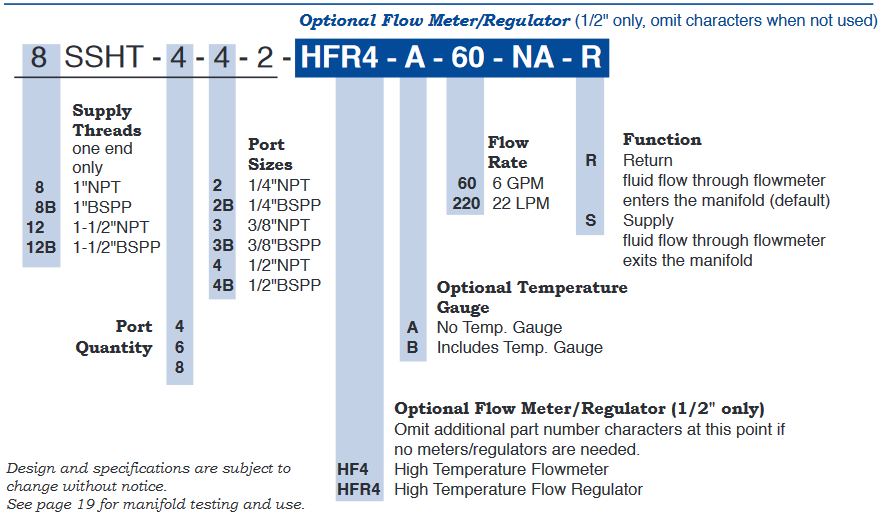

Model Number

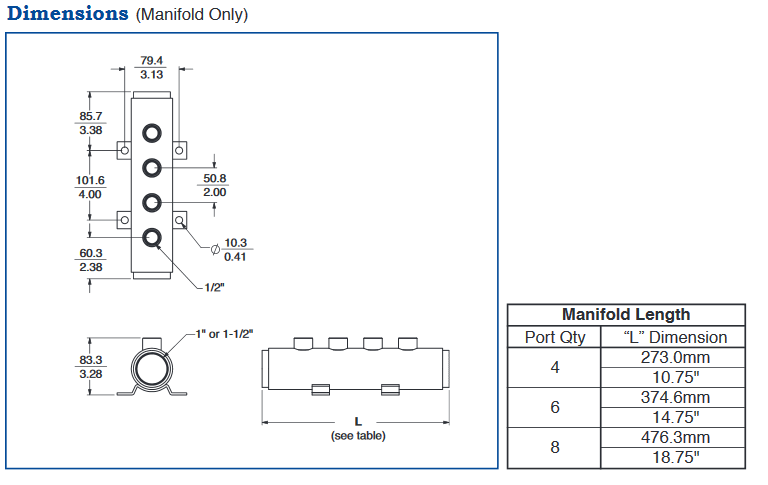

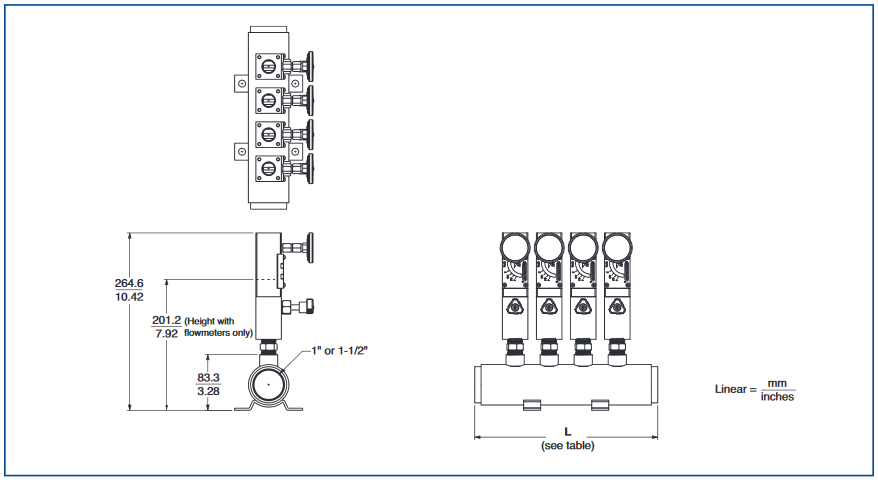

Dimensions